Producing Fertilizers with Recycled Phosphate

Phosphate rock is an increasingly scarce source of phosphorous, and methods are underway to recover and recycle phosphates from other sources such as human sewage, animal manure and waste ash. ICL Fertilizers Europe’s goal is to replace phosphate rock with secondary phosphates. \

Phosphorus is an essential element for plant growth that cannot be replaced. As phosphate rock becomes scarcer, we are looking at various alternatives. We see a possibility of recycling phosphate. Currently, available secondary phosphate, found in sewage sludge as well as in meat & bone meal ash, is used for landfill. The potential to use this untapped resource of phosphate exists.

We are in the process of developing the proper technologies and working with governments on the relevant regulatory requirements. Investments were already made and the first projects will be in Amsterdam and Ludwigshafen. We expect to start producing products that are based on secondary phosphate by 2019.

ICL The Netherlands Amfert receives a subsidy for an innovative Phosphate recycling project

In 2017, ICL The Netherlands Amfert (Phosphate BU) received a subsidy of 500,000 € from the Dutch Province of Noord-Holland (Regional Government in the Netherlands) to enable ICL to invest in an installation to use recycle phosphates as a raw material ICL’s fertilizer plant in Amsterdam. This subsidy demonstrates the importance of investing in innovations that will lead to a circular economy.

To successfully use recycled phosphates in the plant, investment is needed to acquire storage silos and other equipment required to feed waste ash from sewage sludge and bone meal into the plant’s acidulation unit. This investment will allow ICL Amsterdam to substitute up to 25% of phosphate rock with recycled sources. In addition to the significant financial benefits to be gained from this substitution, there also exist substantial environmental benefits. The Dutch government’s investment in this project will allow a circular phosphate economy, i.e using a valuable ingredient more than once and increasing recycling rates for food production. This innovative effort is unprecedented in the global Phosphate industry.

Currently, there are no other known fertilizer producers utilizing such a phosphate feedstock. The project demonstrates ICL's deep innovative culture as well as its commitment to sustainability, and further strengthens its cooperation with local authorities in the environmental area.

SYSTEMIC - Being part of a circular solution to biowaste

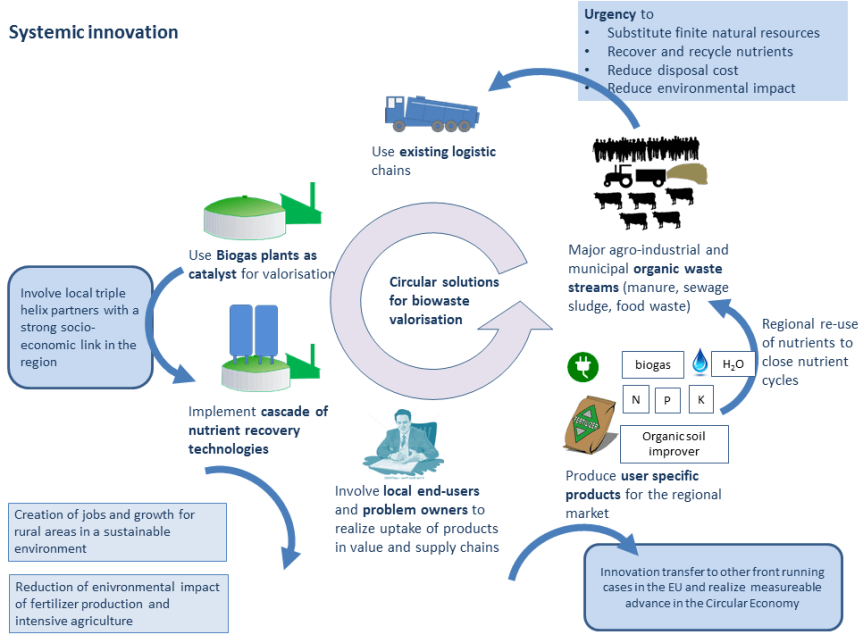

Systemic Innovation

The goal of the SYSTEMIC project is to create ways to implement new nutrient recovery and reuse (NRR) technologies on five state-of-the-art anaerobic digestion demonstration plants in order to demonstrate that the combination of anaerobic digestion and nutrient recovery forms a prerequisite for the valorization of bio-waste in an economically viable manner. This creates a pathway for a circular economy.

This circular approach offers an economically viable solution for the processing of biowaste while reducing CO2 emissions and preventing nutrient losses.

Nutrient Platform - Partnering to Create a “Circular Economy” for Phosphorus

Life on earth is dependent on nutrients. Nitrogen, phosphorus and potassium (N, P and K) constitute the three major nutrients required for plant growth and are crucial for the world’s food supply chain. There are

currently no artificial substitutes for phosphorus and potassium.

ICL The Netherlands Amfert is a member of the Nutrient Platform, a cross-sector network of Dutch organizations that believe in a pragmatic approach towards nutrient scarcity. The Nutrient Platform unites water, agriculture, waste and chemistry with the government, knowledge institutes and NGOs to achieve a goal of recovering phosphorus from ‘waste’ streams recycling it and using phosphorus more sustainably.

ICL is one of the leading companies in the Netherlands in recycling phosphates.

ICL The Netherlands Amfert is one of the Nutrient Platform’s success stories. The company is one of the Netherlands leaders in recycling phosphates. A good example is co-operation between ICL’s phosphate plant in Amsterdam and the water company, Waternet, which is also a member of the platform. Waternet collects several residuals from the Amsterdam sewage system, among which is struvite, a phosphate mineral. ICL uses struvite as a raw material in its production process as a source for phosphorus, nitrogen and magnesium. The goal of ICL The Netherlands Amfert is to replace 150,000 metric tons of mined phosphate rock with phosphorus from secondary raw materials, such as sewage sludge, ash, meat and bone meal ash, wood ash and struvite by the year 2025.

In October 2016, ICL, other members of the Nutrient Platform and the Dutch Government signed an agreement, ‘Ambition Nutrients 2018’, to further increase nutrient recycling.

an inspiring example of closing the phosphate loop”

Mrs. Sharon Dijksma, Dutch State Secretary for the Environment

Developing Products with a Higher Sustainability Value @ ICL Iberia Iberpotash

Struvite is a mineral composed of magnesium, ammonium, and phosphate. Its composition makes it a potentially marketable product for the fertilizer industry. Struvite production is one of the alternative processes of phosphorus removal and recovery from wastewater

effluents.

Typically, human and animal sewage contain ammonium and phosphate. Magnesium is added to the mixture to control the crystallization of struvite. An innovative R&D project at ICL Iberia Iberpotash contributes to the increased sustainability value of struvite by using Magnesium, a by-product of the potash production process.

A closed cycle is created by recovering nutrients from human and animal sewage and industrial waste to produce a fertilizer which is then used to produce food for human and animal consumption.